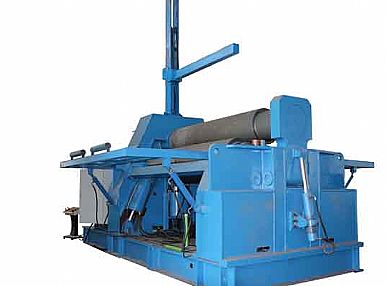

4-roll rolling machine

4-roll plate rolling machine

W12 series 4-roll plate rolling machine is used for the pre-bending and rounding of cylinders in pressure vessels, machinery, hydropower, construction and other industries. It also has the functions of rounding and leveling. The friction between the rollers drives the lower rollers and side rollers to rotate, which provides torque for the rolled sheet. The lower roller, side roller and tipping frame are hydraulically driven uniformly. The lower roller is raised and lowered vertically, and the side roller is inclined to rise and fall. The pre-bending clamps the steel plate by lowering the lower rollers, and the side rollers are inclined to rise to realize the pre-bending of the end of the plate.

Advantage:

The pre-bending of the plate only needs to be loaded once.

There are many shapes that can be rolled, including round, arc, and tapered under certain conditions.

Right-angled edges are smaller.

Shaping and flattening of the plate can be done directly on the device.

Disadvantages:

When working, the two side rollers need to be repositioned several times, which reduces the work efficiency.

The complex structure is not conducive to maintenance and maintenance.

In the current market, the performance of four-roller coilers is much worse than before, and they have been replaced by three-roller coilers. In some developed countries, four-roller coilers have been eliminated even 10 years ago. With the growing maturity of the three-roller rolling machine technology, this trend is becoming more and more obvious in China. Although the four-roller rolling machine has its own advantages, the impact of the three-roller rolling machine on the four-roller rolling machine market It will be even greater in the future.