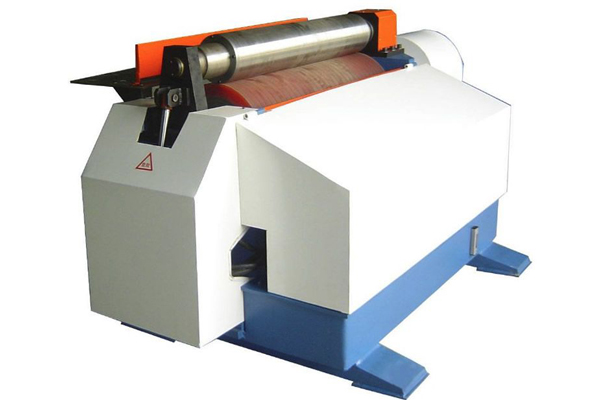

Hydraulic 2-roller rolling machine

Main features of hydraulic 2-roller rolling machine:

1. The two rollers rolling machine is a new type of rolling machine. The upper roll is a steel roll, and the lower roll is a steel roll core with an outer elastic layer. The plate is placed between the two rolls and the distance between them is adjusted to make it contact-pressurize-the lower roll deforms, and the plate is locally deformed, driving the two rolls Rotate to make the sheet bend continuously.

2. It can be molded at one time, with high production efficiency, high geometric accuracy of the product, good surface quality, simple structure, minimum number of rollers, simple operation, and easy to realize the numerical control of the production process.

3. Wide range of applications, such as thin-walled pipes, ventilation pipes, chimneys, filters, solar water heaters, automobile exhaust pipes, liquid storage (gas) tanks, etc.

4. Degree of equipment automation: manual feeding, automatic rolling, and automatic discharging.

5. Use PLC to control the whole machine to improve the reliability of the equipment.

Main specifications and technical parameters of hydraulic 2-roller rolling machine:

Input voltage 380V / 50Hz

Pressing pressure 6-10MPa

Hydraulic power 5.5kW

Coil thickness 0.3-4mm

Rolled workpiece width 300-1000 mm